Continuous Monitors provide operators with instant feedback on the status and functionality of their wrist strap

and/or workstation. They detect split-second failures when the wrist strap is still in the "intermittent" stage. This is prior to a permanent

"open" which could result in damage to ESD sensitive components. Continuous Monitors verify the ground integrity of both the operator and ESD

workstation and eliminate the need for periodic testing (and record keeping).

Dual Polarity Technology provides true continuous monitoring of wrist strap functionality and operator safety

according to accepted industry standards. Dual-Wire Continuous Monitors provide redundancy; even if one dual-wire wrist strap conductor is

severed, the operator still has a reliable path-to-ground with the other conductor.

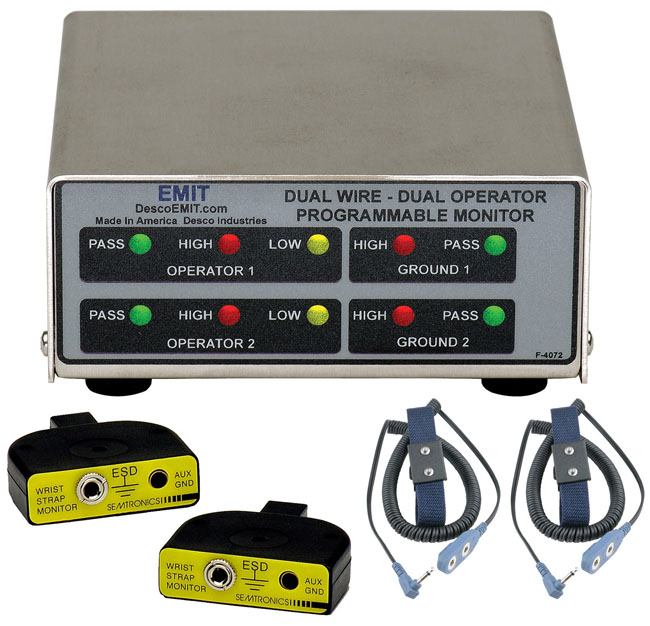

The Dual Operator Programmable Monitor continuously monitors:

• Two operators wearing dual-wire wrist straps

• Two ESD worksurfaces

The Dual Operator Programmable Monitor uses low voltage steady-state DC continuous loop technology to continuously

monitor dual-wire wrist strap functionality.

The Zero Volt Monitor continuously monitors:

The Zero Volt Monitor continuously monitors:

• Two operators wearing dual-wire wrist straps

• Two ESD worksurfaces

The Zero Volt Monitor uses resistive loop technology that allows the operator to typically be near zero volts with respect

to equipment ground.

The Zero Volt Monitor (ZVM) Solo continuously monitors:

The Zero Volt Monitor (ZVM) Solo continuously monitors:

• One operator wearing a dual-wire wrist strap

• One supervisor wearing a dual-wire wrist strap

• One ESD worksurface

• One metal tool fixture

The ZVM Solo's Dual Polarity Technology uses dual-wire wrist cords to place positive voltage on one line and negative voltage

on the other, resulting in near zero voltage at the operator.